What Is External Wall Insulation

External wall insulation is a crucial aspect of maintaining a comfortable and energy-efficient home.

In this article, we will explore the importance of external wall insulation, its benefits, and how it works.

We will also discuss the different types of external wall insulation, the steps involved in the installation process, and the factors to consider before getting started.

We will address potential issues that may arise with external wall insulation. Join us as we delve into the world of external wall insulation and its impact on your home.

What Is External Wall Insulation?

External Wall Insulation (EWI) is a process of adding a layer of insulation material to the exterior of a building’s walls, significantly enhancing thermal efficiency and reducing moisture issues, as highlighted by Ian Rock in the Haynes Home Insulation Manual.

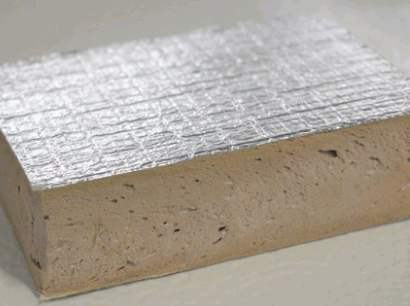

This method involves fixing insulation material, such as expanded polystyrene or mineral wool boards, onto the outside of existing walls, providing a protective barrier that helps retain heat within the property.

External Wall Insulation is versatile and can be applied to various wall types, including brick, concrete, and even timber. Enveloping the building with a layer of insulation, not only reduces heat loss but also regulates internal temperatures efficiently. It acts as a shield against external elements, preventing moisture ingress and dampness, which can lead to structural damage over time.

Why Is External Wall Insulation Important?

External Wall Insulation is crucial for improving a building’s thermal efficiency, complying with Building Regulations, and reducing the risk of dampness and condensation, as supported by the Energy Saving Trust and various insulation systems.

Gain insights: Does External Wall Insulation Work On Cavity Walls

What Are The Benefits Of External Wall Insulation?

The benefits of External Wall Insulation include improved thermal efficiency, reduced condensation, and significant energy savings, as endorsed by the Energy Saving Trust.

By improving thermal efficiency, External Wall Insulation helps to regulate indoor temperatures more effectively, keeping your home warm in winter and cool in summer. This not only enhances overall comfort but also reduces the need for constant heating or cooling, thereby cutting down energy consumption. By creating a barrier against moisture, this insulation minimizes condensation issues that can lead to dampness and mold growth within the walls.

The energy savings associated with External Wall Insulation can be substantial over time, leading to lower utility bills and a reduced carbon footprint. This eco-friendly solution not only benefits homeowners financially but also contributes to a more sustainable environment.

How Does External Wall Insulation Work?

External Wall Insulation works by covering the exterior walls, including solid walls and cavity walls, with effective insulation systems that create a thermal barrier.

Through this process, a layer of insulation material is applied to the external surface of the walls. This insulation material, which can include materials like expanded polystyrene or mineral wool, helps prevent heat loss and regulate indoor temperatures. By reducing heat transfer through the walls, External Wall Insulation helps improve energy efficiency and reduce heating costs. It also plays a crucial role in protecting the building structure from weather elements and enhancing its overall lifespan.

What Are The Different Types Of External Wall Insulation?

There are several types of External Wall Insulation materials and systems, each with unique properties and benefits tailored to different building requirements.

Expanded Polystyrene (EPS)

Expanded Polystyrene (EPS) is a popular insulation material known for its high thermal efficiency and cost-effectiveness in External Wall Insulation projects.

One of the key properties of EPS is its ability to effectively regulate indoor temperatures by minimizing heat transfer through walls. Its closed-cell structure traps air, providing excellent thermal insulation. Due to its lightweight nature, EPS is easy to handle and install, making it a preferred choice for construction projects. EPS is resistant to moisture, mold, and mildew, ensuring durability and longevity in insulation applications.

Mineral Wool

Mineral Wool is an effective insulation material for External Wall Insulation due to its excellent moisture resistance and fire-retardant properties.

These properties make Mineral Wool a highly sought-after choice for protecting buildings from moisture damage and fire hazards. Its ability to resist moisture ensures that it maintains its insulation efficiency over time, even in humid conditions. Mineral Wool’s fire-retardant nature provides an added layer of safety, reducing the risk of fire spreading within the walls of a structure. For those looking to enhance the thermal performance and safety of their buildings, Mineral Wool stands out as a reliable and durable solution.

Phenolic Foam

Phenolic Foam is an advanced insulation material that offers superior thermal efficiency and fire resistance for External Wall Insulation applications.

One of the key advantages of Phenolic Foam as an insulation material lies in its exceptional thermal performance. The superior thermal efficiency of Phenolic Foam helps buildings maintain a consistent internal temperature, reducing the dependency on heating and cooling systems. Its high R-value ensures that less heat escapes through the walls, leading to significant energy savings for the occupants. Phenolic Foam’s excellent fire resistance properties make it a reliable choice for External Wall Insulation, enhancing the overall safety of the building.

What Are The Steps Involved In Installing External Wall Insulation?

Installing External Wall Insulation involves a series of methodical steps, from preparing the walls and applying insulation materials to fixing and securing the boards, followed by finishing and rendering the surface to ensure optimal Building Insulation.

Preparation Of The Wall

The preparation of the wall is a crucial first step in External Wall Insulation, involving cleaning and repairing the surface to ensure proper adhesion of the insulation materials.

Properly preparing the external wall before applying insulation not only enhances the effectiveness and durability of the insulation system but also helps in maintaining the overall aesthetics of the building. Thorough cleaning of the surface is essential to remove any dirt, debris, or contaminants that could hinder the adhesion process. Repairing any cracks, holes, or damaged areas on the wall is vital to create a smooth and uniform substrate for the insulation materials. By investing time and effort into wall preparation, you can significantly improve the performance and longevity of your External Wall Insulation system.

Application Of Insulation Boards

The application of insulation boards involves attaching the selected insulation materials to the prepared wall surface, ensuring a consistent and secure fit.

One common technique for securing insulation boards is to use adhesive specifically designed for this purpose. The adhesive is applied evenly on the back of the boards before firmly pressing them against the wall. To further enhance the secure fit, mechanical fasteners such as screws or nails can be used at regular intervals.

Ensuring that the boards are tightly butted together without any gaps is crucial to prevent heat loss or air infiltration. Once all boards are in place, edges and joints can be sealed with appropriate sealants for added insulation efficiency.

Fixing And Securing The Boards

Fixing and securing the insulation boards is essential to maintain their stability and effectiveness, typically involving mechanical fixings and adhesive methods.

One of the common methods used for securing insulation boards is through mechanical fixings, which involve fastening the boards directly onto the wall or substrate using screws, nails, or anchors. This provides a strong and reliable attachment that can withstand environmental factors.

Another widely used technique is the application of adhesives, which bond the insulation boards to the surface. The choice of adhesive is crucial to ensure proper adhesion and longevity of the insulation system.

The key to a successful External Wall Insulation project lies in the proper installation and securing of insulation boards to guarantee their stability and effectiveness over time.

Finishing And Rendering

The final step of finishing and rendering involves applying a protective and decorative render over the insulation system to enhance the building’s appearance and durability.

This process not only adds aesthetic value to the structure but also serves as a crucial protective shield against weather elements and wear and tear over time. Protective render creates a barrier that helps prevent moisture penetration, thus safeguarding the building from potential damage. The decorative render allows for customization, enabling architects and homeowners to achieve the desired look and feel for the exterior. It’s a meticulous task that requires skill and precision to ensure a flawless finish that enhances both visual appeal and structural integrity.

What Are The Factors To Consider Before Installing External Wall Insulation?

Before installing External Wall Insulation, it is essential to consider factors such as climate and location, building type and structure, and budget and cost to ensure that the chosen insulation materials and systems are suitable for the specific properties and requirements of the building.

Climate And Location

The climate and location of a building significantly affect the choice of insulation properties, as different materials perform variably in diverse weather conditions.

For instance, regions with extremely cold temperatures require insulation materials with excellent thermal resistance to prevent heat loss and maintain indoor warmth efficiently. On the other hand, areas prone to high humidity necessitate insulation that effectively resists moisture absorption, reducing the risk of mold and rot formation.

The selection of insulation materials is crucial in achieving optimal energy efficiency and comfort inside a building. R-value, which measures the material’s thermal resistance, is a key factor to consider when determining the most suitable insulation for a climate-specific application.

Building Type And Structure

The type and structure of the building play a critical role in determining the appropriate insulation method, especially considering whether the walls are solid or cavity walls.

Solid walls, as the name suggests, are made up of a single continuous layer, typically of brick or stone, which can make them susceptible to heat loss without adequate insulation.

Cavity walls, on the other hand, have an inner and outer layer with a gap in between. This cavity allows for the installation of insulation materials, such as foam boards or mineral wool, providing better thermal efficiency compared to solid walls.

Budget And Cost

Budget and cost are significant factors in choosing the right insulation materials and systems, as they determine the feasibility and scope of the External Wall Insulation project.

When considering insulation options, it is crucial to account for the financial implications, as the budget will dictate the type of materials and systems that can be utilized.

The cost of different insulation solutions can vary widely, impacting not only the initial investment but also long-term savings on energy bills.

The budget constraints may influence the overall timeline of the project and the quality of insulation that can be installed.

What Are The Potential Issues With External Wall Insulation?

Potential issues with External Wall Insulation include moisture and damp problems, structural damage, and challenges arising from poor installation practices, which can compromise the effectiveness and lifespan of the insulation system.

Moisture And Dampness

Moisture and dampness are common issues in External Wall Insulation, often arising from inadequate ventilation or compromised insulation materials.

When moisture seeps into the insulation material, it can lead to reduced thermal efficiency and promote mold growth, compromising the structural integrity of the building. Dampness can create an ideal environment for pests to thrive, further deteriorating the insulation and causing potential health hazards.

Proper ventilation is crucial in controlling moisture levels in External Wall Insulation, allowing for the escape of trapped moisture and preventing condensation buildup. Investing in high-quality insulation materials that offer resistance to water penetration is essential to mitigate the risks posed by moisture and dampness.

Structural Damage

Structural damage can occur if the External Wall Insulation is not properly installed or if the building’s walls are not adequately prepared to support the added weight.

When External Wall Insulation is not installed correctly, the risk of cracks, moisture penetration, and detachment from the building’s façade increases significantly. Improper installation can create air gaps, leading to decreased energy efficiency and potential mold growth. If the existing walls are not prepared properly, the additional load from the insulation could strain the structure, causing issues such as bowing or bulging walls.

Poor Installation

Poor installation of External Wall Insulation can lead to multiple issues, as emphasized by BBA/BRE reports, including reduced thermal efficiency and increased risk of moisture ingress.

These consequences not only impact the overall energy performance of the building but also compromise the structural integrity of the walls over time. Cracks, gaps, and poor adhesion caused by improper installation practices can result in water infiltration, leading to mold growth, degradation of insulation materials, and potential damage to the building structure.

Without professional installation, there is a higher likelihood of thermal bridging, air leakage, and uneven insulation coverage, all of which can significantly diminish the effectiveness of the system and increase energy consumption. This highlights the critical importance of adhering to industry standards and guidelines to ensure the longevity and efficiency of External Wall Insulation.